Rushnu’s CarbonCatalyze™ is designed to overcome the challenges of carbon capture by making it scalable and profitable. It integrates carbon capture with chemical production, creating valuable products with broad industrial applications. By leveraging widely used hardware familiar to EPCs and producing high-value outputs for host customers, we minimize scale-up risks and make carbon capture viable for both small and large CO₂ emitters.

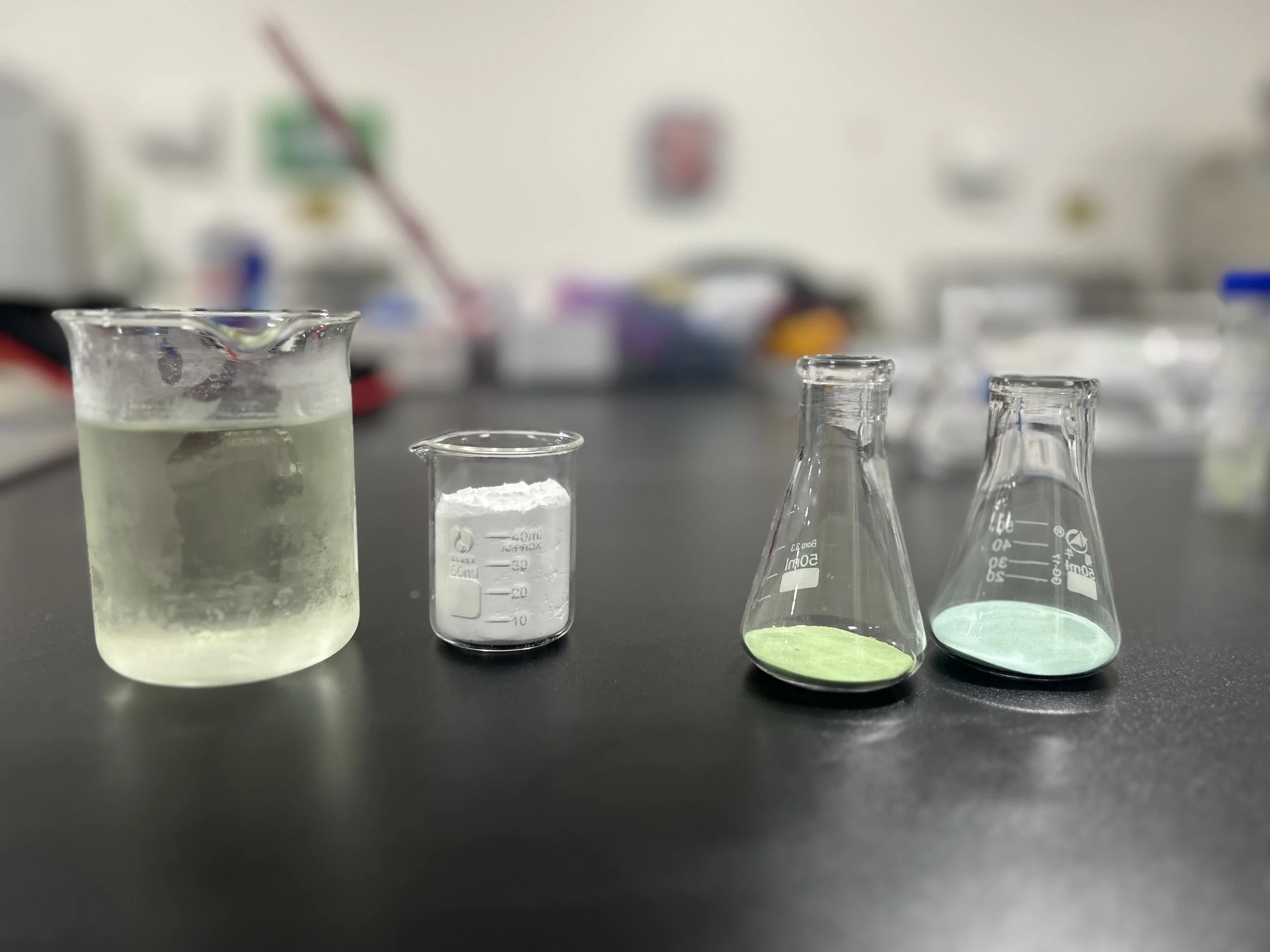

We're kicking off our first field test for a customer in California—here’s a look at the system in action!

Transforming Carbon Capture Technology

Traditional carbon capture and storage (CCS) methods isolate CO₂ and store it underground, where it mineralizes over thousands of years—a slow and costly process that depends heavily on subsidies and provides no immediate revenue. Rushnu’s CarbonCatalyze™ technology disrupts this model by capturing CO₂ and rapidly mineralizing it in a single step, producing most stable form of mineral that prevent atmospheric re-entry. Unlike conventional CCS, this method generates immediate value by transforming emissions into profitable by-products, turning carbon capture from a cost center into a revenue-generating solution for industries seeking a more sustainable footprint

A Dual Catalyst System for Continuous Productivity

At the core of CarbonCatalyze™ is a dual-catalyst process designed for efficiency and profitability: a mineralization catalyst initially reacts with CO₂ from flue gas, transforming it into stable minerals, while a secondary catalyst regenerates the primary mineralization catalyst through a thermal process, releasing valuable by-product. This approach not only enhances sustainability by recycling catalysts but also creates an additional revenue stream from the production of by-product.

Rushnu's CarbonCatalyze™ is recipients of NSF SBIR Phase I award for the project titled "System for High Efficiency Continuous Single-step Carbon Capture and Mineralization." “The industrial sector currently has few financial incentives to sequester CO₂. The technology will address this gap by reducing the energy and associated costs required for capture and conversion of CO₂, generating revenue through the production of sustainable by-products. The ability to produce valuable co-products will be particularly beneficial to industries reliant on raw materials.”

By deploying CarbonCatalyze™, host industries not only achieve their net-zero targets but also generate additional revenue through the production of valuable co-products, creating financial incentives for the adoption of carbon capture technologies. Learn More

Sustainable Integration with Existing Infrastructure

Rushnu’s CarbonCatalyze™ technology is designed to integrate seamlessly into existing industrial operations, enabling facilities to reduce carbon emissions while generating essential chemicals on-site. This system aligns with circular economy principles by transforming CO₂ emissions into valuable industrial inputs, rather than simply disposing of them. The modular and scalable nature of CarbonCatalyze™ makes it adaptable for a range of industries—from wastewater treatment to chemical manufacturing—allowing businesses to achieve their carbon reduction goals while supporting a low-carbon economy without the need for substantial capital investments.

Immediate and Efficient CCS

CarbonCatalyze™ rapidly mineralizes CO₂ from industrial flue gases into stable compounds like calcium carbonate, achieving immediate sequestration without the need for long-term storage. Unlike traditional CCS systems that require CO₂ to be injected into deep geological formations, our process transforms emissions into solid minerals on-site, providing an efficient, permanent solution to carbon capture challenges.

Revenue-Generating By-products Used On-site

By transforming CO₂ emissions into valuable chemicals, CarbonCatalyze™ offers a profitable approach to carbon capture. The technology produces essential by-products that are frequently utilized by the host customer, further enhancing operational efficiency and on-site production capabilities. This by-product generation not only offsets the cost of capture but also turns carbon capture into a revenue stream, making it economically viable without relying on subsidies or carbon credits.

Closed-Loop Catalyst Regeneration and Reuse

The dual-catalyst system at the heart of CarbonCatalyze™ allows for continuous regeneration of the mineralization catalyst, ensuring efficient and sustainable operation. The secondary catalyst thermally regenerates the primary catalyst, enabling it to be reused with minimal degradation and reducing the need for constant replacement. This closed-loop design minimizes waste and lowers operational costs, making the technology more sustainable and resilient over time.

Adaptable and Scalable Design

CarbonCatalyze™ is modular and scalable, allowing it to be tailored to various industrial settings, from water treatment facilities to steel production plants. Its flexible design enables integration with existing infrastructure, providing industries with an accessible pathway to reduce emissions while producing valuable chemicals on-site. This adaptability supports a range of applications, helping industries achieve their sustainability goals without requiring major capital investments.

"We are thrilled to partner with Rushnu as they embark on proving their technology. This will help SVCW – and the wastewater industry as a whole – achieve our mission of protecting public health and the environment."

SVCW General Manager Teresa Herrera

“Partnering with Rushnu is in line with our Climate Action Plan goals to reduce emissions, support innovative decarbonization technologies, and be a leader in local climate action. We look forward to the impact this project will have on our community and beyond.”

City of Livermore City Manager Marianna Marysheva